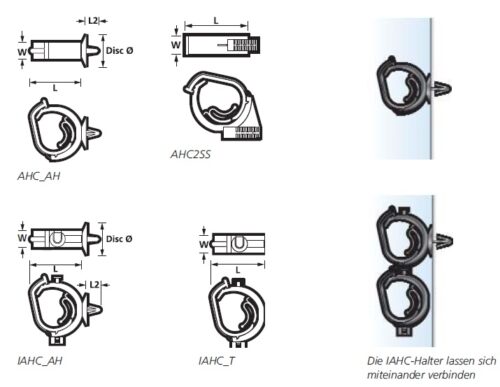

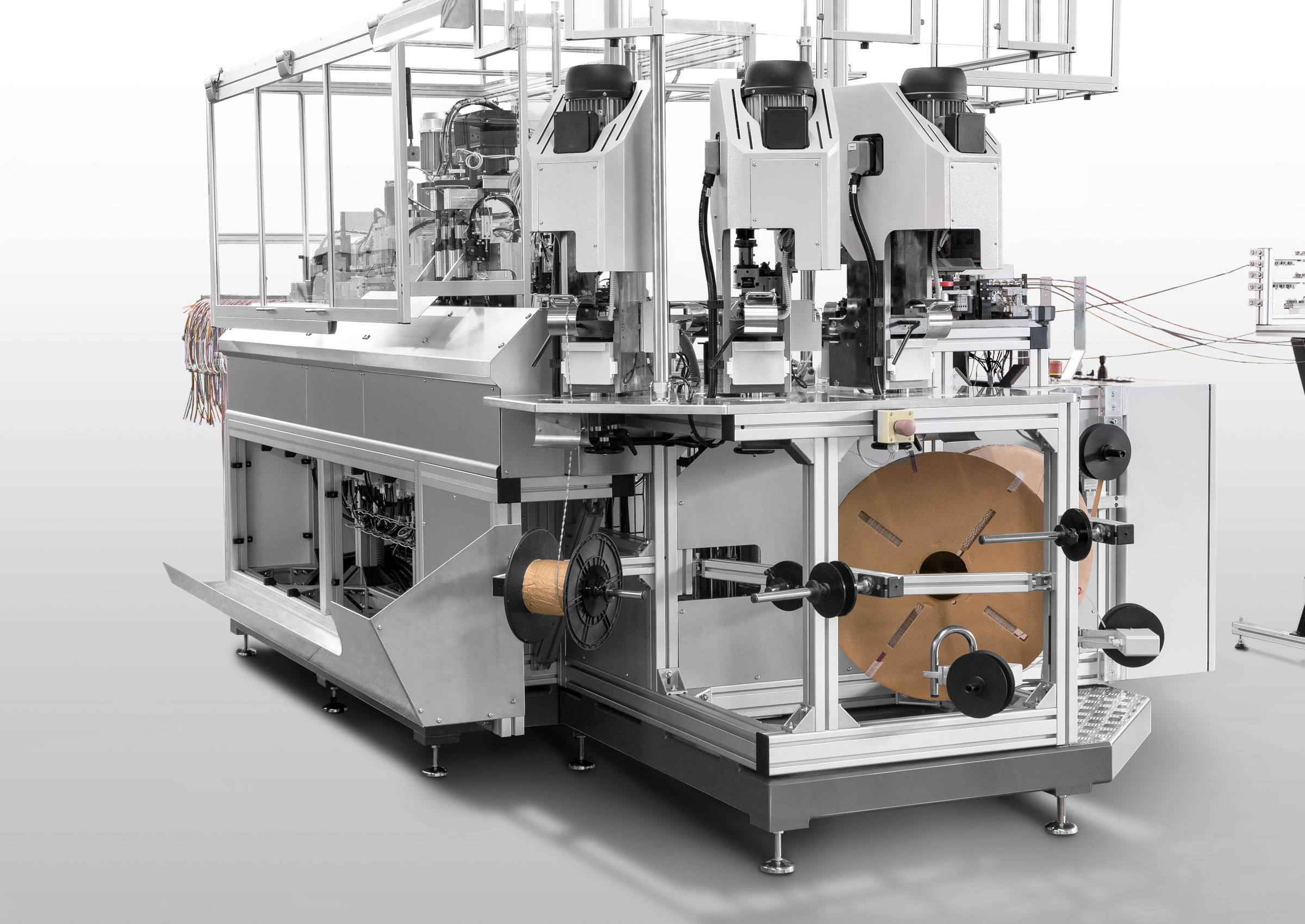

Neuste, patentierte Lösung zur vollautomatischen Herstellung.

InTeCon S IDC

Beschreibung

InTeCon S

Fully automatic terminating machine for IDC Connector

Features

Fully automatic terminating machine for IDC Connector

MAIN FEATURES

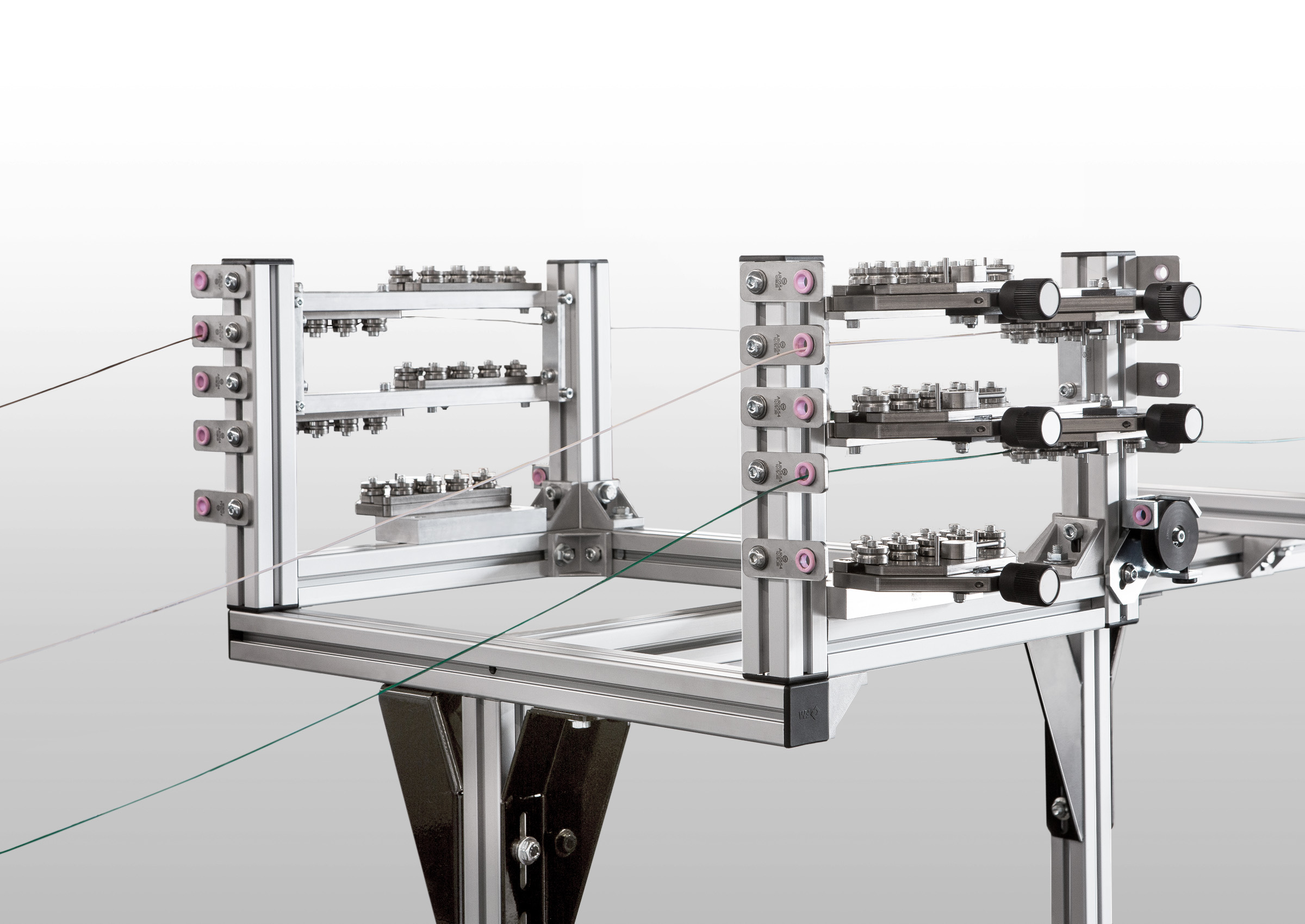

– Feeding system: up to 10 different wires, wire length freely programmable

– Parallel and crossing wires as well as loops or one-side wire terminations are producible

– Min. wire length = 150 mm (Loops), 55 mm (Free wire)

– Max. wire length = 3000 mm (Loops), 1500 mm (Free wire)

– Simultaneous processing connectors with different number of ways, coding versions etc.

– Max Production configuration: 44 contact positions for Rast 2,5, or 24 contact positions for Rast 5

– Connector loading system without machine stop

– Terminating Unit with fine adjustment termination height

– Test device for the correct wire position in the connector

– Continuity Test (optional)

– Coding station (optional)

– Test device of the correct key cutting (optional)

– Selective destroying unit of bad harness (optional)

– User friendly HMI based on Windows O.S.

– internet connection for remote assistance

– Conveyor guide for good harnesses

– Expulsion of bad harnesses

– CE conformity

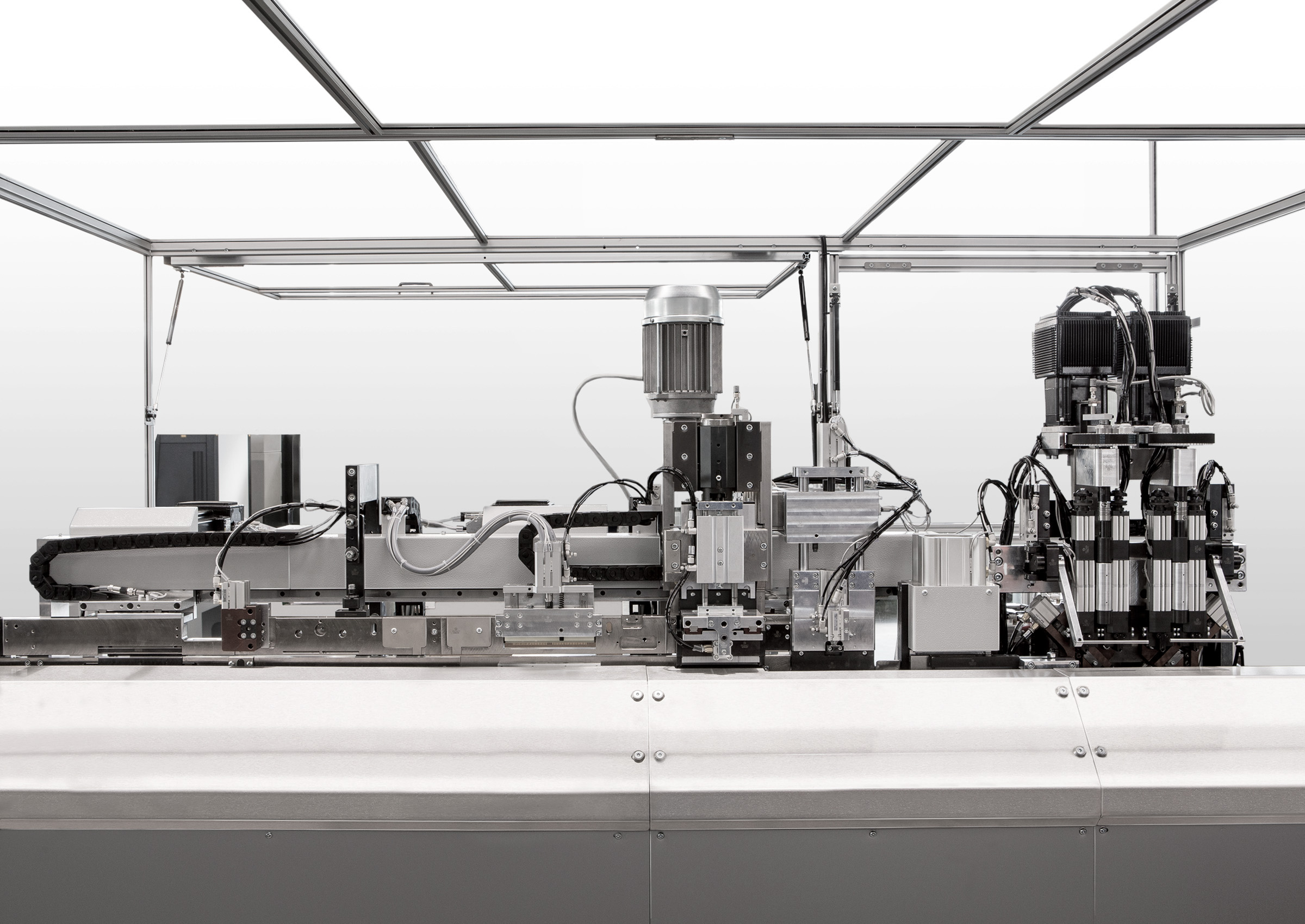

TECHNICAL DATA

– Power supply: 3P + N + PE 400 VAC, 50 Hz, 7 kW

– Air supply: 7 bar

– Air consumption: approx. 150 Nl/min

– Noise level < 80 dB(A) – Dimensions: 3500 x 4700 x h 2000 mm (h 2200 mm safety shield open)

– Weight: approx 1000 kg

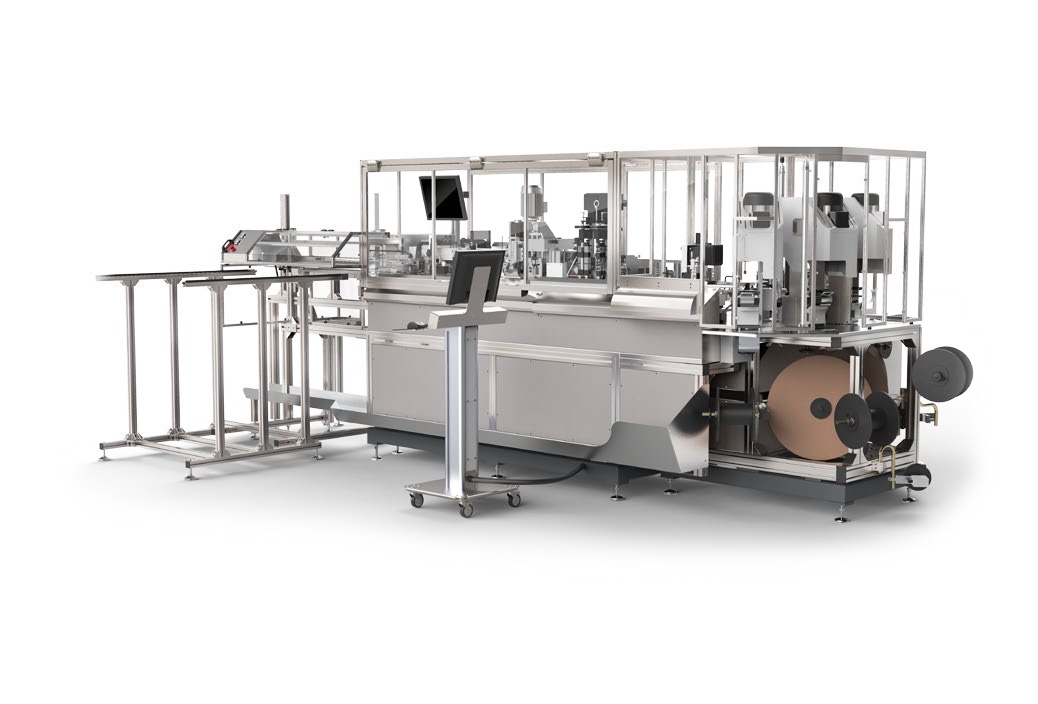

CRIMP MODULE

– Max 3 Crimping units, with CFA

– Wire Feeding up to 6 different, length freely programmable

– Min. wire length = 60 mm (Free / Crimped / Stripped wires)

– Max. wire length = 1500 mm (Free / Crimped / Stripped wires)

– Carrier strip chopper (optional)

– Paper take-up (optional)

– Sleeve Insertion Unit (optional)

– Seal Station Unit (optional)

– Dimensions: 1300 x 1800 x h 2800 mm (safety shield open)

– Weight: approx. 1000 kg

![Intecon-S_re1-frontale-210614-DEF[1]](https://www.aac-kabelbearbeitung.de/wp-content/uploads/2017/01/Intecon-S_re1-frontale-210614-DEF1.jpg)

![Intecon-S-_-Horizontal_Footprint-1[1]](https://www.aac-kabelbearbeitung.de/wp-content/uploads/2017/01/Intecon-S-_-Horizontal_Footprint-11.jpg)

![Intecon-S-_-Vertical_Footprint-1[1]](https://www.aac-kabelbearbeitung.de/wp-content/uploads/2017/01/Intecon-S-_-Vertical_Footprint-11.jpg)

![Intecon-KM-012-scaled[1]](https://www.aac-kabelbearbeitung.de/wp-content/uploads/2017/01/Intecon-KM-012-scaled1.jpg)

![Easy-S-KM-024-scaled[1]](https://www.aac-kabelbearbeitung.de/wp-content/uploads/2017/01/Easy-S-KM-024-scaled1.jpg)

![Easy-S-KM-028-scaled[1]](https://www.aac-kabelbearbeitung.de/wp-content/uploads/2017/01/Easy-S-KM-028-scaled1.jpg)